Setting up an Optical Shop

Given that the prevalence of Refractive Error is high and largely unaddressed, it makes strategic sense for an eye care provider to expand his services to include spectacle dispensing.

Spectacles are the simplest solution to refractive error because they are cheaper, involve less technology and are easier to dispense than other correction options like contact lenses and refractive surgery.

As an eye care provider by dispensing spectacles you can ensure that your patients do receive the necessary correction and that the spectacles are of good quality (the correct power, appropriate lens and frames etc.,).

It has been found that patients prefer unique spectacle designs and models instead of a standard frame design. As patient, have been found willing to pay for this “Vanity component", the dispensing service can be made sustainable.

At Aravind, we have observed that 10% to 25% of the total outpatients need refractive correction. This large volume justifies a dedicated set up for dispensing spectacles.

Today, setting up a spectacle shop is fairly risk- free as the spectacle market is quite well-established, globally. With many players in the market, both in the corporate as well as unorganized sector, the raw materials are available at fairly cheap cost.

Spectacle dispensing is a fairly simple procedure with minimal training needs. With sufficient demand being created in-house and the low cost of goods, this could easily go beyond being a sustainable venture and can generate a surplus.

Equipping an optical shop

Besides the showroom infrastructure and the necessary shelving arrangement for the stock, certain minimum equipment will have to be invested in for sales as well as for processing the lens to get the right power and to fit them into frames. The range of equipment necessary for spectacle dispensing, again, varies with the variety of products and services provided.

For sales and order taking

One needs only basic instruments for taking the various measurements of the patient’s face. This could range from a simple ruler to a sophisticated digital pupillometer.

Processing equipment

- Surfacing is the process by which the power is generated on the lens surface by creating the desired curvature. Lens surface generators or surfacing machines are also available-from basic manual models to fully automated CNC machines.

- Edging of lenses is done to shape them in a way that they can be fitted into the frame. These equipments are available in a wide range in terms of automation and sophistication.

Other essential tools include

- Trial lens set or lensmeter – to determine power of lens.

- Marking, chipping and cutting instruments – to trace and roughly cut the lens to the shape of the frame before fine edging is done on the manual edger.

- Screwdrivers – to fit the lens into metal frames.

- Frame warmer – to enable the lens to be fitted into plastic frames.

- Adjustment pliers – for adjusting the frame.

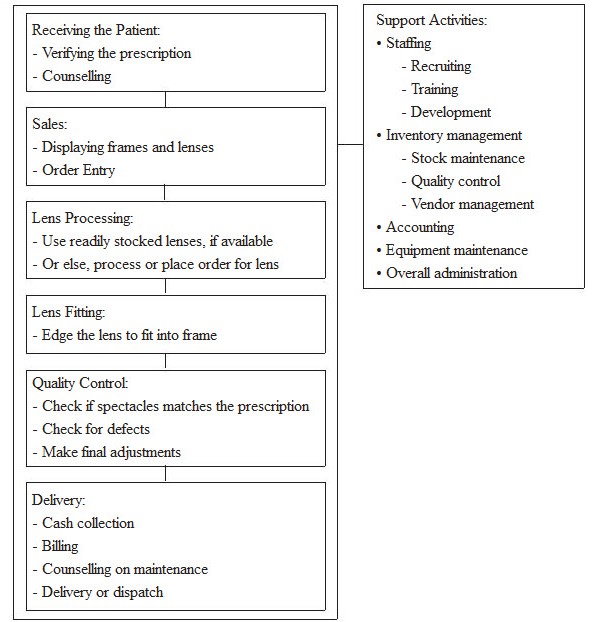

Workflow in a typical optical shop

It must be noted that not all the above processes need to be part of your own dispensing set up. This will vary based on your capacity and circumstance. The following unit will show you which processes can be outsourced and why.

The set up will vary depending upon the number of spectacles you expect to sell. In order to be sustainable, the expected demand should justify the resources employed.

The following table offers recommendations for setting up a dispensing service based on expected demand

| No. of orders per day | Space (sq. ft) |

Staffing | Inventory | Process |

| Fewer than 10 | 50 to 100 | - 1 sales person | Frames only | -Sales only

- Outsource all processing activities |

| 10 to 25 | 200 | - 2 sales persons

- 1 technician for edging |

Ready lenses*

& Frames |

- Edging and fitting

- Outsource surfacing |

| 25 to 100 | 400 | - 4 to 5 sales persons

- 3 to 4 technicians for edging - 3 Administrative staf |

Ready lenses

& Frames |

- Edging and fitting

- Outsource surfacing |

| Over 100 | 600 | - 8 to 10 sales persons

- 4 to 6 technicians for edging & surfacing - 4 Administrative staf |

Frames,Ready

& Blank lenses** |

- Edging and fitting

- surfacing |

*Ready lenses – these are lenses readymade with commonly occurring powers, these are available in the market

** Blank lenses – these are base lenses which have to be surfaced to get the required power

When should you outsource an activity or process.

In order to remain sustainable and to preserve focus, you might want certain processes to be outsourced and some to be done in-house. The following factors might help you weigh which processes to outsource:

- Volume: The volume of any activity must justify the amount of fixed investment that is incurred for setting up the facility and if one can utilise it with near maximum efficiency.

- Delivery time: It is also necessary to look into the time involved in outsourcing an activity. It might be cheaper to get it done by a contractor but it also might take a longer time. If your priority is to save time you might consider doing it yourself.

- Quality and reliability of contractors: To maintain the quality standards of your product, you will have to check if the contractor is able to deliver equal or better service than if you did it yourself. His service would also have to be reliable.

- Cost in outsourcing: Cost of outsourcing the process must ideally be less than or equal to an in-house arrangement.

- Capacity to manage: Sometimes, cost and volume might dictate that a certain process could be done in-house but we might not have the expertise or the capacity to manage it as well as a contractor would.

- A trade off on all these factors will help decide which activities to outsource and which to arrange for within our set up.

Era of the plastic lens

Earlier, glass lenses were predominantly used for spectacles. It is still so in most developing countries though plastic has been introduced.

Plastic lenses have lesser shelf life and need more sensitive handling. Thus your decision to dispense plastic lenses can have direct implications on your equipment. World over, the trend is moving towards plastic lenses more so because of the benefits it brings to the user and it is fast becoming more affordable.

Supply Chain

The spectacle goods market has evolved over the years making lenses, frames and equipment accessible and affordable even for developing countries. However, small retailers will have to be aware of huge mark- ups down the supply chain that can escalate the prices. Thus, the closer up the chain you go, cheaper it is. With a large number of players in the unorganised sector, price regulations are absent. However, cost is controlled by a very highly competitive environment. Today, China has become a major source of good and inexpensive frames and lenses.

Human Resource

Spectacle dispensing involves human skills in two major areas:

- counselling and salesmanship

- technical skill for fitting and surfacing

Thus, training will have to be structured for both categories of staff. It must include

- Order taking

- Salesmanship

- Product knowledge

- Vendor management

- Inventory management with an understanding of the latest trends and fashion so that appropriate frames are stocked

- Report preparation Equally important is that the training must continuously serve to update staff on new developments, in products and techniques

Spectacles at outreach programmes

Outreach programmes make eye care accessible to rural and remote areas. Thus, it is essential that the service is comprehensive and complete. At Aravind we have observed that 10% of the camp patients need refractive correction and now, dispense spectacles on the spot. This ensures that the patient receives appropriate correction.

In the past Aravind assisted camps were generally focused on cataract services. However, today they provide comprehensive eye care and now, special refraction camps are conducted at schools to address the child population and at industries and offices for the working population.

Finances

The following illustrates the finances involved in setting up an average sized optical shop that handles 25 to 50 orders a day.

-

Initial Costs: Major initial investments for setting

up infrastructure for the dispensing unit include:

-

- Space

- Furniture

- Basic Equipment – manual edger

- Inventory – Lenses & Frames

-

Overheads: Other indirect costs that are usually

incurred are:

-

- Rent

- Electricity

- Stationery

- Salary

- Freight

- Machinery maintenance

- Consumables

- Miscellaneous

-

Recurring Costs: Direct costs incurred in

manufacturing spectacles are for:

-

- Frames

- Lenses

- Accessories

- Direct labour charges

-

The following are the average unit selling prices

of spectacles at Aravind Eye Hospitals, India. (These

prices are neither prescriptive nor indicative of prices

in this region).

- In outreach camps: Rs.200 (US$ 5)

- In the free hospital: Rs.250 (US$ 6)

- In the paying hospital: Rs.500 (US$ 12)

Student exercise

Choose the correct answer

- 1. Setting up an optical dispensing unit is sustainable because

-

a. employees need not be trained

b. there is a large number of people with refractive error

c. lenses can be stocked for a long period

d. patients are willing to buy expensive spectacles

- 2. Which of the following will you NOT consider while deciding to outsource a process to a contractor.

-

a. Price charged by the contractor

b. Time taken by the contractor

c. How frequently the process is used

d.Type of lens needed

- 3.Which of the following is NOT a process involved in optical dispensing.

-

a. Fitting contact lenses

b. Processing lenses

c. Performing cataract surgery

d.Training opticians

- 4. Which of the following is NOT the job of a dispensing optician.

-

a. Manufacturing frames

b. Managing suppliers

c. Maintaining inventory

d.Preparing reports

- 5. The demand for plastic lenses is growing because

-

a. Plastic lenses are cheaper than glass lenses

b. Plastic lenses are clearer than glass lenses

c. Plastic lenses are thinner than glass lenses

d.Plastic lenses are lighter than glass lenses